-

AGRICULTURAL MACHINERY

- BRANDS

- Tractors

- Grain-harvesting combines

-

Sowing machinery

- KUHN Planter 3 Select precision seed drill

- Sowing complex KUHN ESPRO 6000RS

- Precision seeder KUHN KOSMA Select

- Case IH SDX 30/40 pneumatic sowing machine

- BEDNAR OMEGA OO_L sowing machine

- A wide seed drill BEDNAR EFECTA CE

- Grain seeder BEDNAR OMEGA CORSA CN

- Pneumatic precision seed drill KUHN MAXIMA 3 TRM E

- MATADOR MO sowing machine

- Sprayers

- Tillage machinery

-

Harvesting machinery

- Olimac Drago 2 corn harvester

- Olimac Drago GT corn harvester

- Olimac Gold sunflower harvester

- Franco Fabril SF sunflower harvester

- Case IH 3020 TeraFlex

- Case IH Grain harvesters

- Case IH 3050 Varicut

- MacDon FD2 corn harvesters

- Grain reaper Case IH 2030

- Case IH 4408 corn harvester

- Case IH 4412 corn harvester

- PW8 Pick-up Header

- Corn harvester FRANCO FABRIL MH870

- Mower

- Balers

- Rollers

- Telescopic loader

- USED Machinery

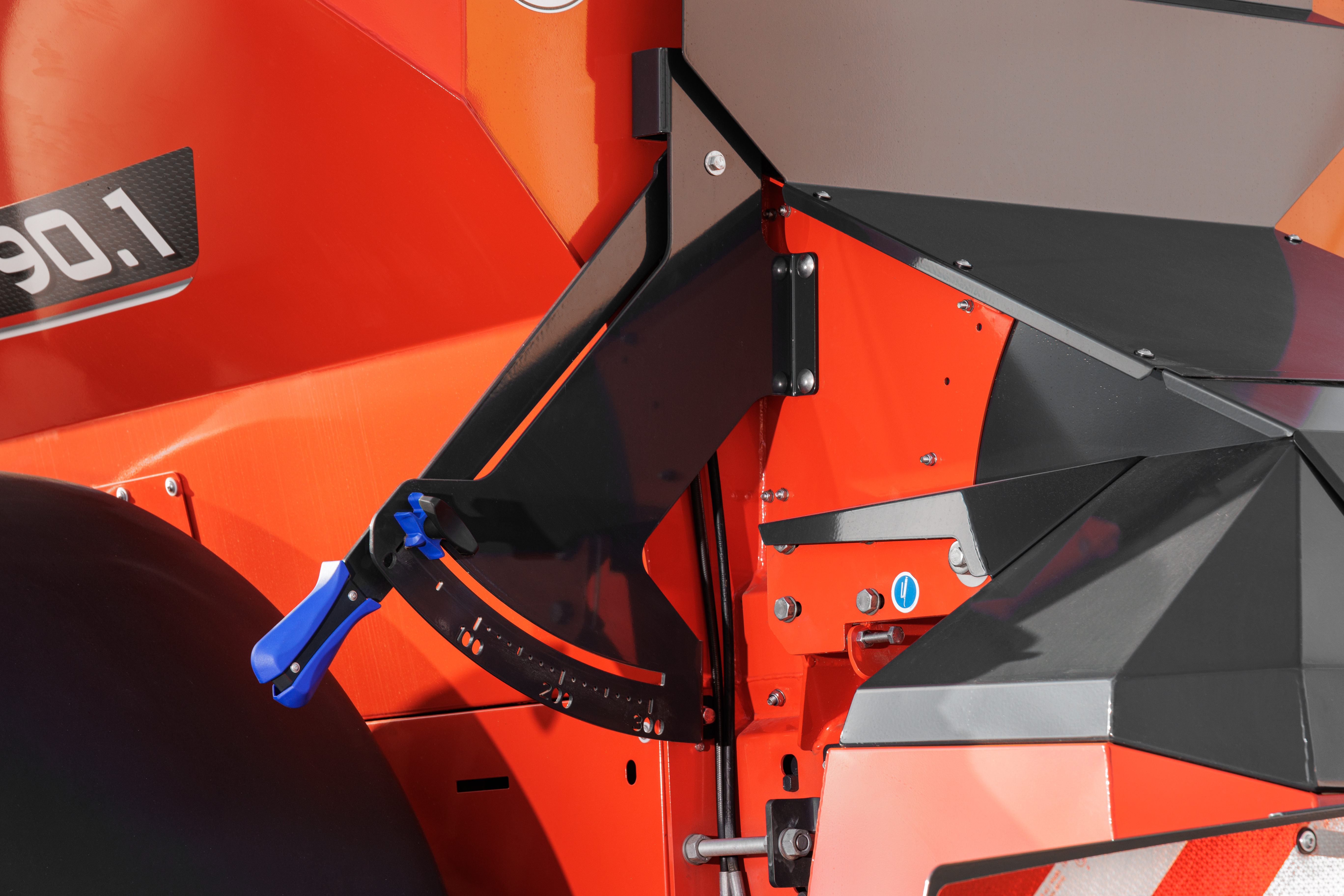

- Large spreader of mineral fertilizers KUHN Axent 90.1 EMC

- combined disc-paw unit KUHN PERFORMER SELECT

- SAFEGUARD WARRANTY

-

PRECISION AGRICULTURE

- AgroDrones & UAV

-

Tractor solutions

- Raven CR7 Field Computer

- XCN - 2050 display

- Дисплей XCN-1050

- XCN-750 display

- Autopilot Electric Motor Drive automatic driving system

- Automatic driving system EZ-Pilot Pro

- AFS AccuGuide precision farming system

- Automatic water system Sveaverken F100

- Raven hydraulic autopilot for unprepared equipment

- Trimble Autopilot automatic control system

- Sprayer solutions

- Combine solutions

- Trailed implements solutions

- Correction service

- Maintenance of data

- USED MACHINERY

- SERVICE

- PARTS

- SPECIAL OFFERS

Large spreader of mineral fertilizers KUHN Axent 90.1 EMC

The KUHN AXENT 90.1 fertilizer spreader is a highly efficient tool with a hopper volume of 9,400 liters. Not only can it spread up to 400 kg/ha in a width of 36 m at a speed of over 20 km/h, with precision, but it can also work in a width of up to 50 m.

It is equipped with an AXIS Power Pack spreading module with a mechanical drive, therefore

low hydraulic flow is sufficient to feed the conveyor belt. Thanks to these properties, it is adapted to a wide range of tractors from 180 hp.

The AXENT 90.1 fertilizer spreader boasts numerous high-tech functions: EMC, CDA, VARISPREAD 8 or PRO, as well as a fully automatic conveyor. A winning combination to ensure the crop gets the right dose of fertilizer and costs are under control.

• Exclusive EMC (Electronic Massflow Control) technology allows for regulation

input rate, independently and automatically from left and right, every second. Idea

simple: the fertilizer flow is measured on each disc so that, in the event of blockage, the flow rate of the corresponding outlet is adjusted immediately and automatically to ensure the correct dose of fertilizer on each side.

• The CDA distribution system makes application more accurate and consistent, even when there are variations in application rate, working width and travel speed. Ultra-slow agitator (17 revolutions over 360°) feeds discs and gently feeds pellets. The specific design of the device for measuring the discharge holes in three points ensures the gradual feeding of the distribution discs evenly. In addition, the output chute directs the fertilizer to the spreading discs to ensure drop point accuracy.

• VARISPREAD equipment allows you to adjust the working width directly from the tractor. ISOBUS terminal. With VARISPREAD 8, the fertilizer rate can be reduced gradually in 8 sections, 4 on each side. The VARISPREAD PRO sectional control consists of two electric motors, SpeedServos, which are 2.5 times faster than traditional cylinders. SpeedServos enable fast and continuous adjustment of the working width by changing the drop points and fertilizer application rate on one-meter plots. This leads to the spread of a fan perfectly adapted to the shape of the site, with optimal coverage even at high speeds.

• A fully automatic conveyor is located in the antechamber above the spreading discs. This means that the driver does not need to activate it to provide fertilizer to the AXIS Power Pack.

Accurate and regular supply of fertilizers to the spreading modules is guaranteed!

The AXENT 90.1 fertilizer spreader also boasts numerous comfort features that enhance the experience of the experienced user.

• Bunker with silent block suspension. Hopper vibrations are reduced and distribution is more accurate and regular. Driving comfort is provided both in the field and on the road.

• Four weighing cells make it possible to monitor the amount of fertilizer in the hopper continuously and directly on the ISOBUS terminal or using the Spreadset application on a smartphone. The real advantage is in the optimization of logistics and predictable replenishment.

Main technical characteristics:

Working volume: 9400 liters;

Drive type: mechanical from GDP 540 rpm;

Weight system: yes, 4 weight sensors;

Mass flow control system: EMC, on each disk separately;

Management of sections: VARISPREAD system;

Automatic opening and closing of shutters: OPTIPOINT system;

Maximum distribution rate: 500 kg/min;

Distribution discs: S6 VXR+ DISCS 24-36M. Optionally up to 50 meters;

Braking system: basic performance, pneumatic;

Wheels: VF 520/85 R42;

Suspension: silent blocks.

It is equipped with an AXIS Power Pack spreading module with a mechanical drive, therefore

low hydraulic flow is sufficient to feed the conveyor belt. Thanks to these properties, it is adapted to a wide range of tractors from 180 hp.

The AXENT 90.1 fertilizer spreader boasts numerous high-tech functions: EMC, CDA, VARISPREAD 8 or PRO, as well as a fully automatic conveyor. A winning combination to ensure the crop gets the right dose of fertilizer and costs are under control.

• Exclusive EMC (Electronic Massflow Control) technology allows for regulation

input rate, independently and automatically from left and right, every second. Idea

simple: the fertilizer flow is measured on each disc so that, in the event of blockage, the flow rate of the corresponding outlet is adjusted immediately and automatically to ensure the correct dose of fertilizer on each side.

• The CDA distribution system makes application more accurate and consistent, even when there are variations in application rate, working width and travel speed. Ultra-slow agitator (17 revolutions over 360°) feeds discs and gently feeds pellets. The specific design of the device for measuring the discharge holes in three points ensures the gradual feeding of the distribution discs evenly. In addition, the output chute directs the fertilizer to the spreading discs to ensure drop point accuracy.

• VARISPREAD equipment allows you to adjust the working width directly from the tractor. ISOBUS terminal. With VARISPREAD 8, the fertilizer rate can be reduced gradually in 8 sections, 4 on each side. The VARISPREAD PRO sectional control consists of two electric motors, SpeedServos, which are 2.5 times faster than traditional cylinders. SpeedServos enable fast and continuous adjustment of the working width by changing the drop points and fertilizer application rate on one-meter plots. This leads to the spread of a fan perfectly adapted to the shape of the site, with optimal coverage even at high speeds.

• A fully automatic conveyor is located in the antechamber above the spreading discs. This means that the driver does not need to activate it to provide fertilizer to the AXIS Power Pack.

Accurate and regular supply of fertilizers to the spreading modules is guaranteed!

The AXENT 90.1 fertilizer spreader also boasts numerous comfort features that enhance the experience of the experienced user.

• Bunker with silent block suspension. Hopper vibrations are reduced and distribution is more accurate and regular. Driving comfort is provided both in the field and on the road.

• Four weighing cells make it possible to monitor the amount of fertilizer in the hopper continuously and directly on the ISOBUS terminal or using the Spreadset application on a smartphone. The real advantage is in the optimization of logistics and predictable replenishment.

Main technical characteristics:

Working volume: 9400 liters;

Drive type: mechanical from GDP 540 rpm;

Weight system: yes, 4 weight sensors;

Mass flow control system: EMC, on each disk separately;

Management of sections: VARISPREAD system;

Automatic opening and closing of shutters: OPTIPOINT system;

Maximum distribution rate: 500 kg/min;

Distribution discs: S6 VXR+ DISCS 24-36M. Optionally up to 50 meters;

Braking system: basic performance, pneumatic;

Wheels: VF 520/85 R42;

Suspension: silent blocks.

TITAN MACHINERY UKRAINE qualified specialists are trained by our European partners on the regular basis. We are ready to provide you with professional support together with choosing the best solutions for your working conditions.

We are ready to provide all the information about the machinery presented on our website.

Please contact us by the number or e-mail: 0800-50-8080 / sales@titanmachinery.ua

Please contact us by the number or e-mail: 0800-50-8080 / sales@titanmachinery.ua

INDUSTRIES

BRANDS