The Strip-Till Seeder Aligns with Modern Agronomic Trends

09/20/2024

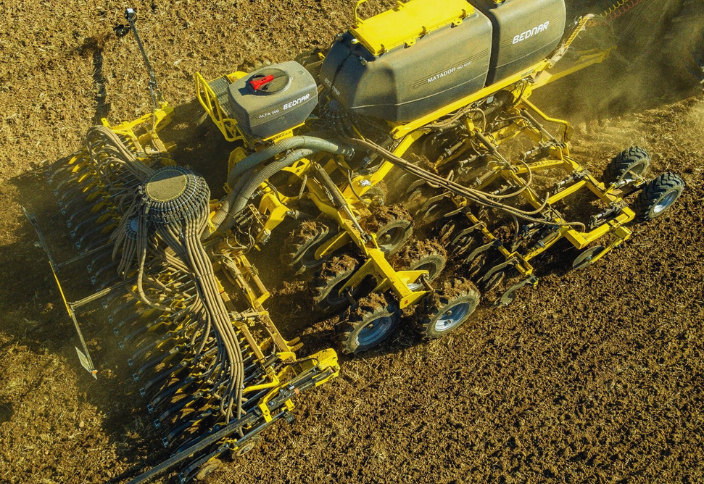

The MATADOR MO seeder is designed for strip-till seeding, in accordance with Strip-Till technology. This method, which combines strip-till soil preparation with simultaneous seeding, offers a revolutionary approach to crop planting. The machine’s design is based on new agronomic and legislative trends in the EU, aimed at reducing herbicide use through mechanical tillage.

With a working width of 6 meters, the MATADOR MO is a highly efficient combined seeder that performs deep strip-till, fertilizer application, and seeding all at once. The primary advantage of this approach is that before seeding, the soil in the strips where future plants will be located is loosened, and fertilizers are precisely applied at the depth of the root zone. Strip-Till technology provides numerous agronomic benefits, such as moisture conservation, erosion protection, better warming and aeration of the soil in the strips, fewer field passes, and more efficient fertilizer use. The seeder is equipped with a pressurized dual-chamber hopper with a total capacity of 5,000 liters (with a 40:60 chamber ratio). Additionally, it can be equipped with the ALFA DRILL 400 microgranulator for sowing small-seed crops between rows or for applying microgranulated fertilizers. The ALFA DRILL control is integrated into the MATADOR MO seeder’s interface.

Strip-Till Soil Preparation

The strip-till section of the machine is equipped with shanks that have robust NON-STOP hydraulic protection with a maximum release force of 870 kg. The maximum lift of the shanks in case of obstacle contact is 30 cm. ACTIVE-MIX shanks provide high-quality soil tillage, breaking compacted layers, and mixing crop residues with the soil. The shanks can be equipped with 40 or 80 mm chisels. The MATADOR MO 6000 seeder has 16 shanks arranged in two rows, with 35 (37.5) cm spacing between them. These shanks are fitted with tips for fertilizer application, either into the soil profile or on the soil surface. The disc section operates after the shanks and is hydraulically adjustable, leveling the soil before the wheel packer, which is suitable for most cereal crops, or for creating ridges, which is ideal for rapeseed.

The two-row rubber-tired roller is a standout feature of the MATADOR MO seeder. The roller has offset wheel placement in two rows, with a large gap between the first and second rows, and each wheel is mounted independently. This design reduces tractor power requirements and prevents wave formation and roller clogging when working in wet conditions. The independent wheel mounting allows for easy replacement in case of a puncture.

Various Aggregation Options

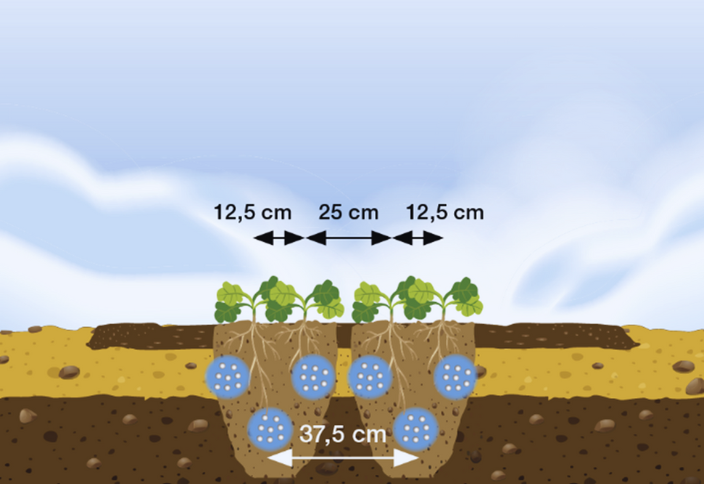

The MATADOR MO can be equipped with the CORSA CN seeding section on the rear three-point hitch for standard sowing of cereals or oilseeds. The seeding section has double-disc openers with parallelogram mounts, with row spacing of 12.5 cm (25 cm, 37.5 cm, etc.), or for twin-row spacing of 12.5 cm with 25 cm spacing between the twin rows. The CORSA CN can be equipped with front implements, such as a CRUSHBAR leveling bar, a FRONTPACK wheel packer, and TURBO or PROFI openers. However, the MATADOR MO can also be aggregated with precision seeders for planting corn, sugar beets, or sunflowers. In this case, every other shank can be deactivated, allowing strip tillage with row spacing of 70 (75) cm. This design is also appealing for farms with less powerful tractors, as it reduces tractor power requirements. The 70 (75) cm row spacing can also be used for sowing winter rapeseed in twin rows, where winter rapeseed planted in twin rows benefits from fertilizers applied in the central tilled strip.

User-Friendly Operation and Convenient Calibration

Ease of operation is a priority for equipment operators. The MATADOR MO is equipped with new BEDNAR EASY CONTROL software, which guarantees user-friendly and well-organized operation. The seeder is compatible with ISOBUS technology and can be controlled via the BEDNAR ISOBUS display. Display series with basic or extended control functions are available.

BEDNAR developers have created a mobile app that simplifies seeder calibration using a mobile phone. The app includes a guide that helps select the appropriate seed roller depending on the seed/fertilizer type, working speed, and seeding rate.

Special emphasis was placed on ease of operation and calibration when designing the MATADOR MO seeder to simplify the operator’s workload.

Continuous Crop Monitoring in Real Conditions

When developing new equipment models, BEDNAR not only monitors the technical characteristics of the machines but also directly tracks the results of their operation.

Recently, we visited a demonstration field where winter rapeseed (mid-late variety Manhattan) had been planted using the MATADOR MO on heavy soil. Crop monitoring shows that the condition of the rapeseed, even with a lower seeding rate under strip-till, is positive, particularly in terms of tillering.

Rapeseed is known for its compensatory ability, so choosing the correct seeding rate and method is crucial. Thanks to strip-till, the MATADOR MO provides better moisture access for the plants, which is particularly important during hot months. This year, with an early spring and high temperatures, presents an excellent opportunity to study the results of strip-till planting for crops sown last fall.

Titan Machinery Ukraine is the official dealer of BEDNAR in Ukraine, offering a wide range of BEDNAR equipment for soil preparation, fertilization, and seeding. We ensure high quality and reliability, enabling maximum results in agricultural activities. Our product range includes the latest models of equipment that meet the modern demands of the agricultural sector and promote efficient resource use.

The equipment is available in our warehouse in Ukraine, enabling prompt delivery across the country. Moreover, we provide professional service support with a highly qualified team of specialists ready to offer technical assistance and repairs, keeping the equipment in optimal condition for effective task performance.

Our experts are always ready to provide consultations, assist with equipment selection, and ensure the necessary technical support to keep your agricultural processes running smoothly and efficiently.

Contact us at 0 800 50 80 80 or leave a request on our website www.titanmachinery.ua.